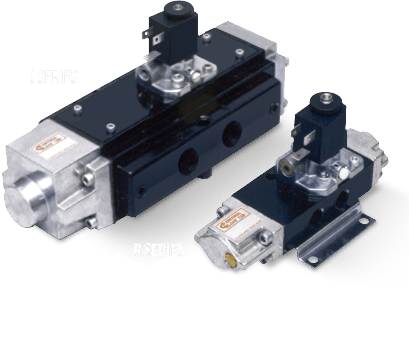

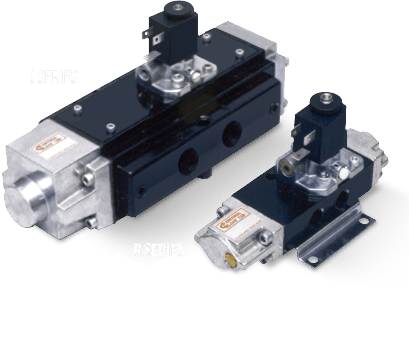

Pneumatic Valves G&J SERIES

G&J SERIES

HIGH FLOW SPOOL VALVES

- 1⁄4", 3⁄8" 1⁄2" NPT PORTS

- 3-WAY OR 4-WAY OPERATION

- PILOT AND SOLENOID OPERATED

- 2 AND 3 POSITION CONFIGURATIONS

- Cv RANGE 1.7 TO 6.6

G Series 3-Way & 4-Way Valves

FEATURES & BENEFITS

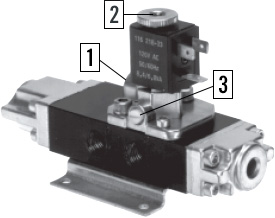

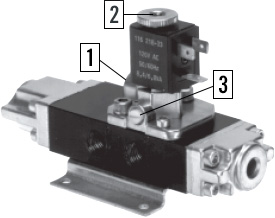

1 |

Standard external solenoid supply enables valve operation for vacuum service for low pressure operations. Remove and discard the pipe plug. Assemble the 10-32 threaded plug. (part no. 116153 plug kit, order separately), with o-ring assembled into the threaded port to block the internal supply connection. Connect the external air supply to the 1/8 NPTF port. |

2 |

Air pressure (50 PSI minimum) introduced at the solenoid exhaust port (10-32 thread) will override the solenoid. This is a convenient way to set-up and troubleshoot circuits without electrical power to the solenoids. |

3 |

Manual locking override is standard. Simply depress and turn the override button to shift the valve. |

Application Information

- Available in pilot and solenoid models only.

- These 1/4" NPTF port valves have self-aligning stacked spacers and O-rings, which assure O-ring seal while allowing increased air flow.

- These valves are ideal for high cycle applications and for operation of larger bore cylinders and air tools.

- The hard anodized, ground and polished spool increases valve life by resisting wear and corrosion while assuring start-ups without hang-ups.

- The ground and polished spool permits operation with no additional lubrication for a cleaner environment and reduced product contamination.

- The low profile aluminum body is lightweight and corrosion resistant.

- These valves are rated at 200 PSIG to 28" of mercury and will operate in high or low pressure or vacuum applications.

- All 4-way valves may be ordered with bottom ports for subplate or manifold mounting.

- Repair kits available.

- Class F coil is rated for 100% duty cycle.

- Standard features include a manual locking override and a pilot override. Override must be depressed and turned to operate.

Specifications

| Lubrication: |

| Valves are pre-lubed and can be operated without air line lubrication. If air cylinders or other air line devices require lubrication, ensure that lubrication oils are compatible with valve seals and of sufficient viscosity to assure adequate lubrication. |

| Flow: | 61.6 SCFM |

| Cv Factor: | 1.72 |

| Weights: |

Pilot — .7 to 1.3 lbs. Solenoid — 1.8 to 3.4 lbs. |

| Minimum Pilot Pressure: |

Spring return — 40 PSI Pilot return — 20 PSI |

| Standard Operating Pressure: |

Pilot — Vacuum to 200 PSI Solenoid — Vacuum to 150 PSI |

| Temperature Range: | -10° to 180°F |

Valve Porting

| 4-WAY | 3-WAY | ||

| Two-position | Three-position | All Models | |

|

Cylinder Ports Open, Inlet Blocked |

All Ports Blocked |

All Models |

G SERIES ORDERING INFORMATION

| Connector Accessories: CONSULT FACTORY FOR ADDITIONAL CONNECTOR OPTIONS | Connectors - without indicator lights or lead wire: CDN = 1/2" Conduit | CSN = Strain Relief |

| G Series dimensional data is available in the G&J Series Catalog |

J Series 4-Way Valves

FEATURES & BENEFITS

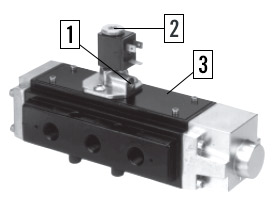

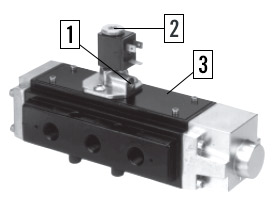

1 |

Standard external solenoid supply enables valve operation for vacuum service for low pressure operations. Remove and discard the pipe plug. Assemble the 10-32 threaded plug. (part no. 116153 plug kit, order separately), with o-ring assembled into the threaded port to block the internal supply connection. Connect the external air supply to the 1/8 NPTF port. |

2 |

Air pressure introduced at the solenoid exhaust port (10-32 thread) will override the solenoid. This is a convenient way to set-up and troubleshoot circuits without electrical power to the solenoids. |

3 |

Low profile die cast aluminum body is lightweight and corrosion resistant. |

Application Information

- Available in pilot and solenoid models only.

- The “J” Series valve has a self-aligned stacked O-ring spacer configuration which allow it to have one of the highest air flow capacities on the market.

- A ground and polished spool permits operation with no additional lubrication for a cleaner environment and reduced product contamination.

- These valves are rated at 150 PSI to 28" of mercury for operation in high and low pressure as well as vacuum applications.

- The anodized polished spool increases valve life by resisting wear and corrosion while assuring start-ups without hang-ups.

- All solenoid actuated models are furnished with Class F coils and external solenoid supply option.

- Coils can easily be interchanged or replaced by removing nut, sliding existing coil off, a new coil on.

- Position the coil connectors where you need them. Simply loosen nut and rotate coil to desired position.

- Molded connectors protect the electrical connections against high humidity and wet environments to meet NEMA 4 classification.

GENERAL SPECIFICATIONS

|

Lubrication: Valves are pre-lubed and can be operated without air line lubrication. If air cylinders or other air line devices require lubrication, ensure that lubrication oils are compatible with valve seals and of sufficient viscosity to assure adequate lubrication. Temperature Range: -10° to 180°F |

||||||

| PORT SIZE | TYPE ACTUATOR | TYPE RETURN | PRESSURE RANGE PSI | MINIMUM PILOT PRES. PSI | FLOW SCFM* | Cv FACTOR |

| 3⁄8" | ALL | Pilot or Solenoid | Vacuum To 150 | 10 15 for detent | 200 | 5.6 |

| 3⁄8" | ALL | Spring | Vacuum To 150 | 20** | 200 | 5.6 |

| 1⁄2" | ALL | Pilot or Solenoid | Vacuum To 150 | 10 15 for detent | 236 | 6.6 |

| 1⁄2" | ALL | Spring | Vacuum To 150 | 20** | 236 | 6.6 |

|

*Flow capacity approximate. [90 PSIG supply, 75 PSIG outlet.] **Including 3-position spring centered. These valves require 50 minimum pressure. |

||||||

Valve Porting

| 4-POSITION | 3-POSITION | |

|

All Ports Blocked |

Cylinder Ports Open |

J SERIES ORDERING INFORMATION

| Connector Accessories: CONSULT FACTORY FOR ADDITIONAL CONNECTOR OPTIONS | Connectors - without indicator lights or lead wire: CDN = 1/2" Conduit | CSN = Strain Relief |

| J Series dimensional data is available in the G&J Series Catalog |